How to Reduce Supply Chain Chaos with AWS Supply Chain

Businesses large and small are turning to AWS Supply Chain to optimize their supply chain processes. And not a moment too soon. As we’ve learned over the last few years, the downside of the complex global supply chains that many companies have established is that they are easily disrupted by events such as pandemics.

Any solution that can keep the supplies flowing for your business can help you keep your customers happy and provide a substantial competitive advantage.

Amazon Web Services (AWS), of course, is well known for its cloud services, including desktop workspaces, servers, and storage. But recently the AWS service offerings have expanded to include tools to optimize supply chains. These solutions incorporate artificial intelligence (AI), internet-of-things (IoT), blockchains, and other advanced technologies.

Many industries can benefit from AWS Supply Chain solutions. The healthcare, retail, transportation, restaurants and hospitality, energy, and even services industries all depend on resilient supply chains to serve their customers, and can realize a competitive edge with AWS Supply Chain.

In this article, we look at the solutions that AWS Supply Chain provides and examine some real-world use cases that ERPA can apply in various industries.

Reduce Overhead and Curtail Risk with AWS Supply Chain

Many companies still use outdated supply chain systems that were implemented prior to the global pandemic. These legacy supply chain processes weren’t designed to tackle current issues.

ERPA’s team of Amazon Web Services (AWS) experts use AWS cloud-based technology, like machine learning (ML) and computer vision, to help your company alleviate pitfalls and keep your overhead costs low, while strengthening your supply chain and unifying data.

Below we go over some of the features included in AWS Supply Chain and explain how our dedicated team can apply AWS’s cloud infrastructure expertise to solve your supply chain problems.

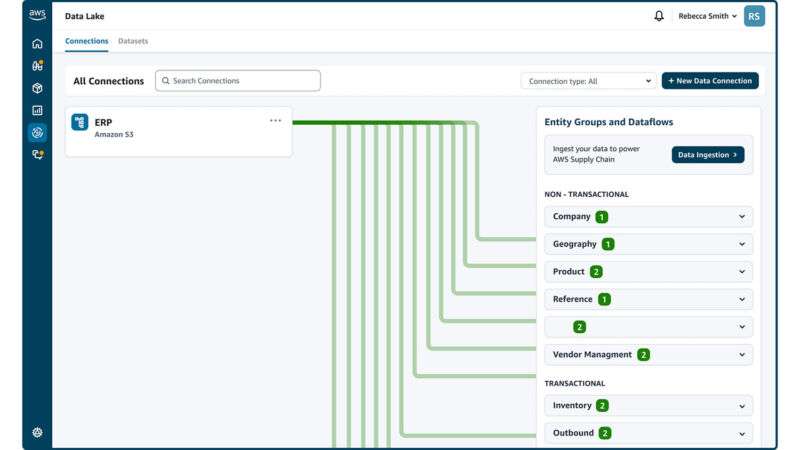

AWS Supply Chain Data Lake

Designed to incorporate machine learning (ML) models pre-trained for supply chain usage, AWS Supply Chain sets up data lakes that extract and transform disparate, incompatible data into a unified model.

Data lakes usees existing ERP systems like SAP S/4HANA and other supply chain management systems to ingest data from multiple sources.

For other variable sources, AWS Supply Chain uses machine learning (ML) and natural language processing (NLP) to connect the dots between source systems to the unified data models, such as data acquired from EDI 856.

Other sources like EDI 850 and 860 have their messages transformed directly using transformation recipes that are predefined yet customizable. Any other sources of data are loaded into an S3 bucket that’s automatically ingested into the data lakes.

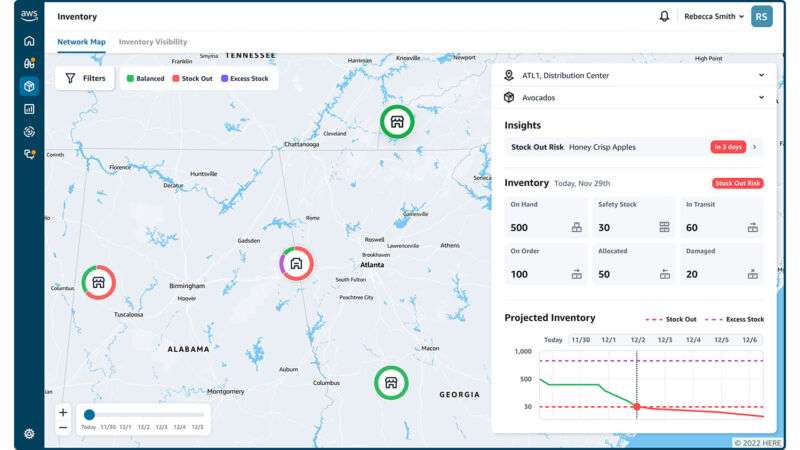

AWS Real-Time Visual Map

Another aspect of AWS Supply Chain that shouldn’t go unnoticed is their Real-Time Visual Map feature. This feature can use a set of interactive, visual end-user interfaces built on a micro frontend (MFE) architecture to contextualize your data onto a real-time visual map.

The subsequent data can be highlighted to reflect both the current inventory, quantity, and inventory health at each location.

The AWS Real-Time Visual Map can delve even deeper into specific facilities, giving inventory managers a view of inventory on hand, in transit, and those that are at potential risk.

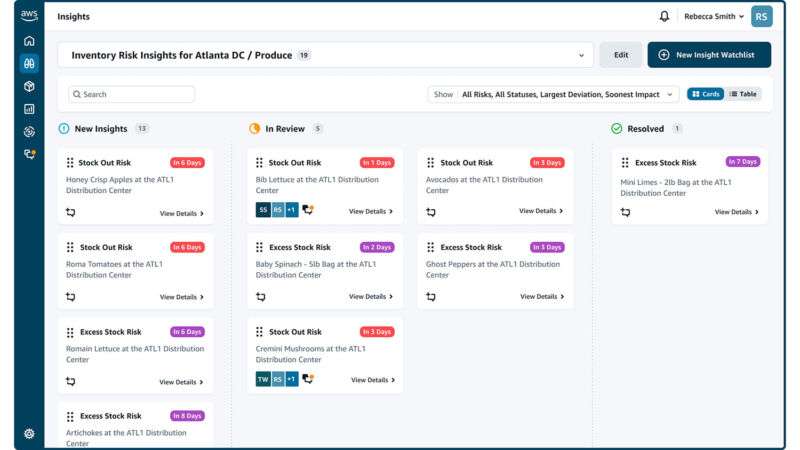

AWS Supply Chain Insights

AWS Supply Chain Insights allows inventory managers to better manage potential risks within their supply chain by using comprehensive supply chain data in the data lakes to then both generate automatic insights and display them on the Real-Time Visual Map.

The AWS Insights feature can also generate accurate vendor lead time predictions by applying machine learning (ML) models to make predictions, giving supply planners info needed to update static assumptions and plan for reducing stock-out or excess inventory risks.

Watchlists can also be made by supply chain leaders by plugging in locations, risk types, and stock thresholds to monitor other potential risks. Team members can even be added as watchers to these watchlists, and AWS Supply Chain can send alerts to all watchlist watchers when a potential risk occurs and where it might happen.

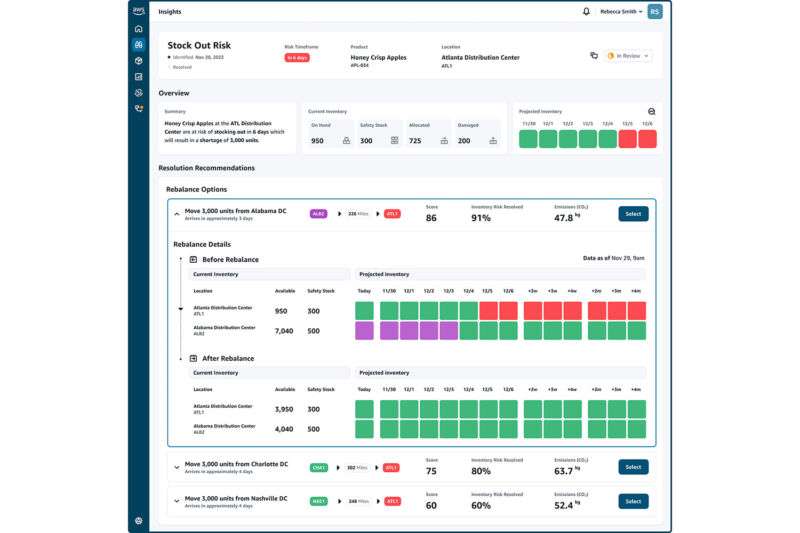

AWS Recommended Actions and Collaboration

AWS Supply Chain can take the ingested data and then evaluate, rank, and share rebalancing options with inventory managers as well as recommended actions for addressing future risks.

Using a score involving the percentage of risks resolved, the distance between facilities, and sustainability impact, recommendation options are then offered and improved over time to best reflect your supply chain and business’s goals.

To help with implementing recommendations and rebalancing actions, AWS Supply Chain includes contextual collaboration capabilities with team chats and messaging. This way, errors and delays caused by poor communication are mitigated, and issues can be resolved faster.

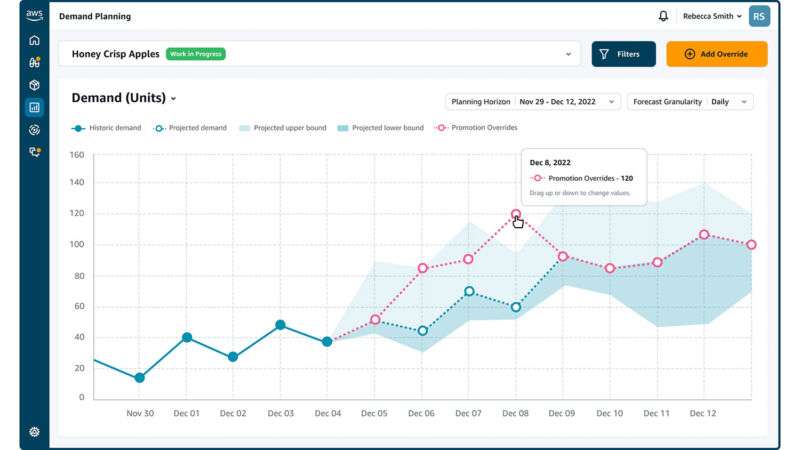

Get more accurate demand forecasts with Demand Planning by AWS Supply Chain.

Demand Planning offers you the ability to empower your demand planners with forecasts that can be adjusted to current market conditions and give collaboration opportunities across teams to avoid waste and excess inventory costs.

AWS Supply Chain Demand Planning

AWS Supply Chain does this by using machine learning (ML) to analyze historical sales data and real-time data, create forecasts, and adjust models to improve accuracy in order to remove manual effort and guesswork behind the scenes.

Also, Demand Planning can constantly learn from changing demand patterns and user input to give even more accurate forecast updates.

Up Your Supply Chain Game with AWS Supply Chain Management

The dedicated features included with AWS Supply Chain can be used in conjunction with the additional products and solutions available within the AWS Supply Chain Management suite of solutions, a part of AWS for Industrial.

ERPA can combine AWS Supply Chain with the powerhouse features available with AWS Supply Chain Management to take your supply chain solutions to the next level.

Here are just a few of the ways that we can apply AWS Supply Chain Management to help solve your supply chain problems:

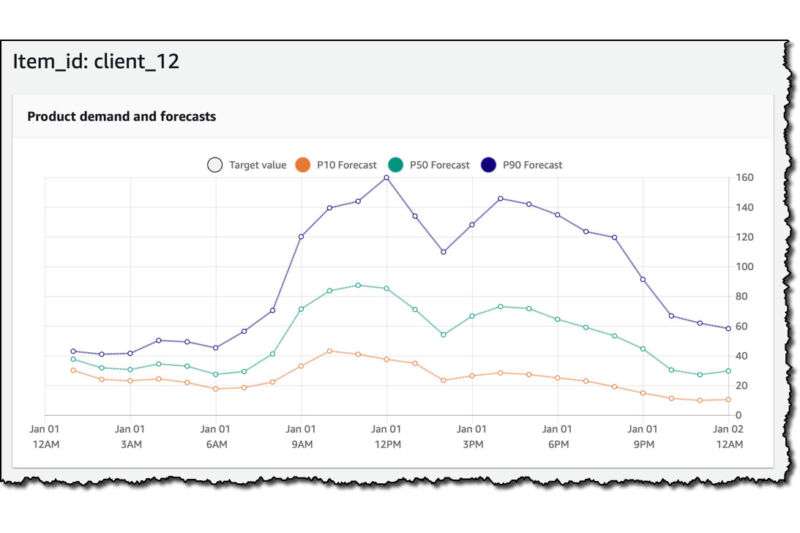

Amazon Forecast

With the Amazon Forecast application, a sophisticated machine-learning (ML) tool, you can load relevant historical data (sales, web traffic, inventory, and more) and product data into the system, and the tool will analyze the data and choose an appropriate algorithm for forecasting. This algorithm becomes the basis for an artificial intelligence (AI) forecasting model that Amazon Forecast trains and optimizes.

The trained model can then be used to generate demand forecasts at the individual products and services level or for entire product lines and can break down these forecasts by various attributes such as geography. You can view these forecasts in the Amazon Forecast application or export the data to your enterprise resource planning (ERP), manufacturing resource planning (MRP), or other downstream system.

Having accurate forecasts gives you the ability to:

- Identify the raw materials or other items that are most at risk and secure backup sources of supply;

- Optimize inventory levels so you have sufficient inventory to meet your needs without excessive carrying costs;

- Plan the right time and quantity for placing orders for limited shelf-life materials;

- Forecast staffing needs for seasonal surges and lulls in demand.

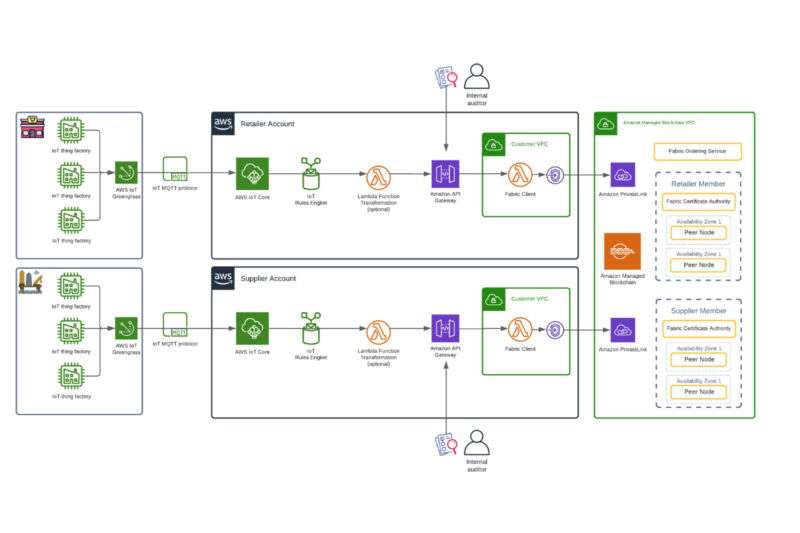

Amazon Managed Blockchain

Although complex global supply chains have enabled businesses to reduce costs and optimize inventory, they have provided the opportunity for unscrupulous parties to inject lower-quality or even counterfeit materials into the supply stream. It becomes difficult to trace the source of quality and reliability issues because of the sometimes murky relationships with upstream suppliers.

One solution that businesses are starting to leverage is blockchain-based tracking and tracing. Amazon’s Managed Blockchain platform enables your entire supply-chain network to document their transactions in a secure shared ledger, thus providing full transparency and real-time status monitoring.

The benefits of this technology include:

- Greater confidence that your suppliers (and theirs) are behaving ethically;

- Better quality control throughout the supply chain;

- Real-time transport updates;

- Certainty of end-product quality and authenticity;

- Immediate visibility into the source of quality issues;

- And more.

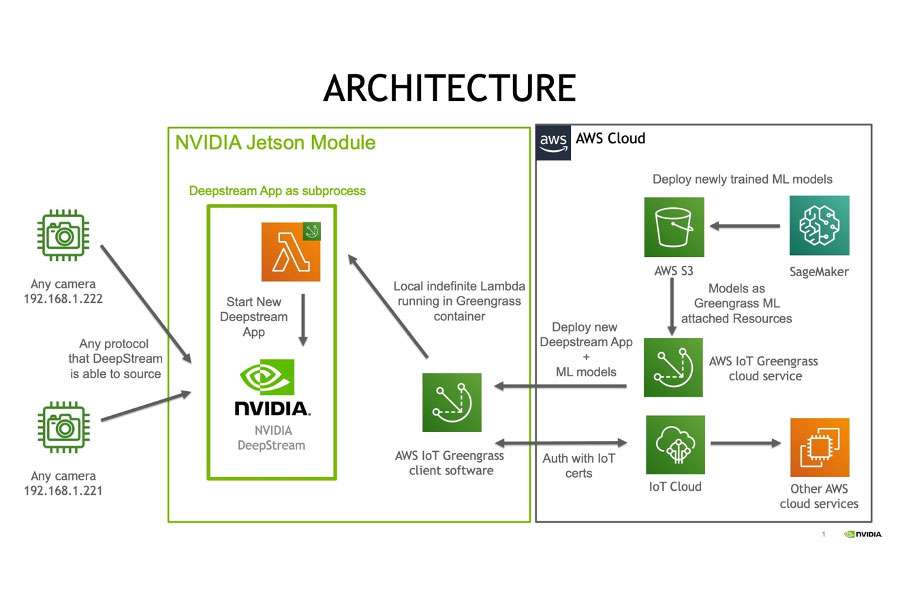

Transportation and Logistics Optimization

Transportation is often among the most fragile links in the supply chain. It can be affected by weather, traffic conditions, vehicle breakdowns, labor issues, and other factors that are out of your control, even if you own or manage the transportation resources.

Even without these influences, it’s tricky to make sure the right personnel and equipment are in the right place at the right time to meet your (or your customers’) transport needs, and that backups are ready to roll if anything goes awry.

Proper logistics planning and optimization requires access to high-volume, detailed data from multiple sources and advanced analytical tools to make sense of it all and inform the right decisions. Numerous AWS services can be brought to bear here:

- Amazon Kinesis Data Streams and Kineses Data Analytics can take in real-time weather and traffic data, process it, and store it in an Amazon Simple Storage Service (S3) resource.

- AWS IoT Greengrass can generate vehicle telemetry data, which can be loaded with Amazon Kinesis Data Firehose.

- In a similar way, data such as driver safety information can be loaded into the system.

- Various database, analytics, and reporting tools can present the right information to the right people.

With all this information available, a solution can be built and customized to predict departure and arrival times, send alerts to drivers and supervisors, meet regulatory requirements, and more.

Reinvent Your Supply Chain with ERPA + AWS Supply Chain

AWS is a complex system of resources and tools that offers high flexibility to meet any data-driven need. This flexibility means that a high level of expertise is needed to design, develop, configure, and test custom solutions to meet your particular needs.

Partnering with ERPA is the shortest path to realizing a robust supply chain solution for your business. Our AWS consultants are experts in the AWS product and service offerings and know how to bring everything together into a solution that brings you maximum benefit for the lowest startup and operational costs.

If your company isn’t already leveraging AWS, ERPA can help you migrate to AWS as well.

Whether you are struggling with supply-chain issues or need to optimize your supply chain, it’s worth your time to look at AWS Supply Chain.

Contact ERPA today to discuss your situation with our AWS Supply Chain consultants and learn more about how ERPA can help reduce your supply chain chaos.